Simultaneous Engineering

Simultaneous Engineering – SE ensures that Design for manufacturability and Design for Assembly, inputs in various area of manufacturing In digital environment are properly addressed by suitable modification / updation in the design. if such issues are not addressed properly in the product and process - design may not work effectively, and this may lead to late design changes. So, SE function helps to minimize number of late changes while productionizing the new product.

This digital study usually requires support of CAD, Line simulation, CED reach, Plant simulation, Ergonomics study, Digital Built.

Require actions are systematically mapped at each Product milestone to meet above objective.

-

Stamping

- Panel Level Manufacturability.

- CAS.

- Yield Improvement.

- Panel Quality & EQAP Deployment for Quality.

-

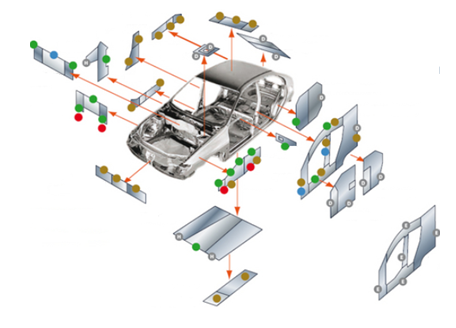

Body In White

- ALP / PLP.

- Spot Accessibility and built tree.

- Simulation for fixture suitability.

- Part Count Reduction, Mig Reduction, Spot Weld Reduction.

-

Corrosion Protection.

- Corrosion resistance simulation.

- Sealant application and EBHS

Geotools Provides all the services related to the Simultaneous Engineering. We have skilled Expertise and require software's.